CNC programmers are responsible for the proper operation and programming of CNC machines using CNC programming that allows sending instructions to motorized tools. How do you become a CNC programmer and what are the day to day responsibilities?

What is CNC programming?

CNC refers to Computer Numerical Control and describes programmable machines that are used for mechanical processes such as milling or drilling. CNC machine programming is a specific set of coding rules that make up CNC software required to run lathes, mills, routers, grinders, laser cutters, and other machines.

This is where a CNC Programmer comes in. They are responsible for the programming, design, and development of this software as well as setting them up to run on CNC machines.

In order to do this, a CNC Programmer must have knowledge of programming languages. The most common programming language used to run CNC machines is G-code (also known as G programming). With G-code, a programmer can control various movements and functions of a CNC tool.

As it stands, CNC Programmers are in great demand since they are generally employed in almost every industry related to manufacturing. They improve automation and flexibility.

In which industries are CNC Programmers most in demand?

- Machinery

- Aerospace

- Nuclear

- Hand tools & equipment

- Automotive

- Medical

- Oil & Gas

- Industrial

- Electronics

Looking for a new job?

» Browse CNC programmer jobs 🔎

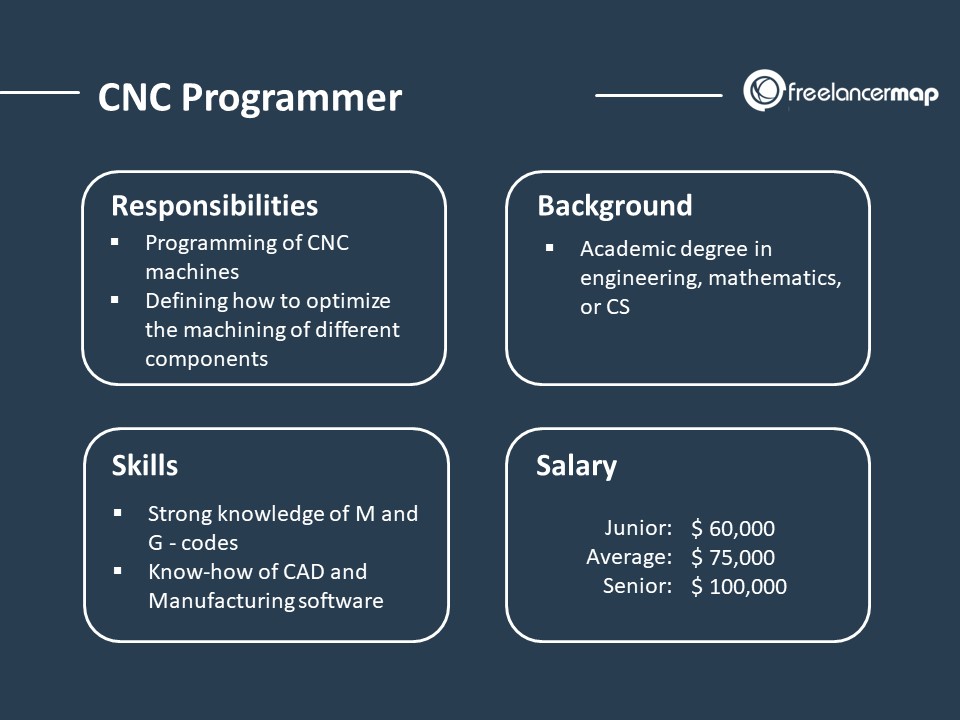

CNC Programmer Responsibilities

CNC lathes mill, drill, or cut materials for the production of goods often require complex programming with special software. A CNC programmer is responsible for the development and programming of this software. They also work on improving the applications of the software in relation to the machine.

In their day to day tasks, they analyze existing machines and their work processes and optimize them if necessary. CNC programmers also train and instruct workers who operate the equipment in question. As part of the optimization process, they also check the use of materials, keeping an eye out for signs of wear and tear, and monitor the repair and maintenance of the equipment.

What are the tasks of a CNC programmer?

- Programming of CNC machines

- Defining how to optimize the machining of different components

- Optimization of the operation of CNC machines for processing time

- Instruction of skilled personnel for the operation of the machines

- Repair and maintenance monitoring of CNC machines

- Defining the manufacturing processes and indicating the necessary tools and devices

- Creating, modifying, testing CNC programs based on workshop drawings, technical data, and instructions from the design department

Skills required

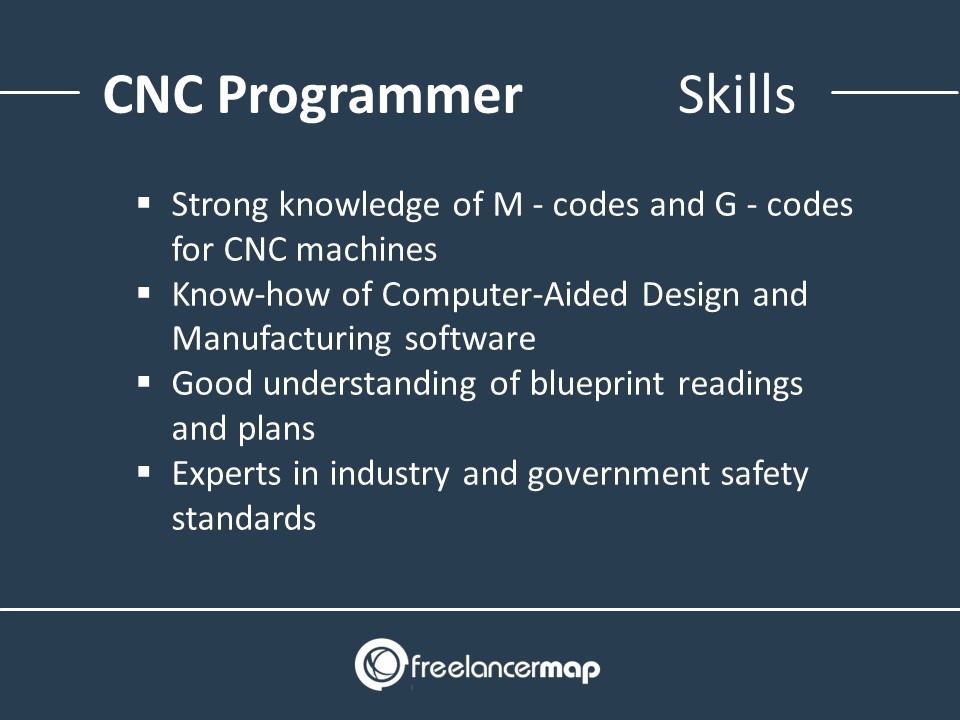

CNC programmers have expertise in the field of computer science – especially coding, and have know-how in the fields of mechanical and systems engineering. Technical skills include knowledge of CAD, manufacturing software, and in the fields of mathematics and physics.

Soft skills include a structured and responsible way of working and logical thinking, especially when working on CNC coding.

What must a CNC programmer be able to do?

- Strong knowledge of G – Codes and M – codes for CNC machines

- Know-how of Computer-Aided Design software – AutoCAD or Solidworks are popular CAD software

- Experience with Computer-Aided Manufacturing (CAM) software – e.g. Powermill, Fusion 360

- Good understanding of blueprint readings and plans

- Experts in industry and government safety standards

- Knowledge of setting drills, mills, and lathes to ensure 100 percent accuracy

- Strong mathematics ability – including trigonometry and geometry

- Keen sense of analysis and logical thinking

Are you looking for a specialist with CNC machines?

> Latests CNC programmer’s profiles⚙️

How do you become a CNC Programmer? Education & Background

In order to become a CNC programmer, an appropriate academic degree lasting 3-4 years is usually required. Degrees in the fields of Computer Science, and/or engineering are suitable options.

Furthermore, In order to get to know the profession of the CNC programmer, it is highly recommended to do an internship in advance in order to be clear about the tasks of the profession before embarking on the career.

Salary

The starting salary for a CNC programmer is about $60,000 gross per year. The average salary is around $75,000 gross per year. The senior salary is $100,000. The salary can be higher in individual cases with the respective income depending on numerous variables, such as the industry and the company, but also on professional experience.

How much does a CNC programmer earn?

| Starting Salary | $60,000 |

| Average Salary | $75,000 |

| Senior Salary | $100,000 |

| Average rate CNC Programmers (2022) | $71/hr |

CNC programmers on freelancermap charge on average:

Rates range between $40 and $96/hour for most freelancers.

The daily rate for CNC programmer (8 working hours) would be around:

Great description, this should encourage young people to get into CNC Machining for a career.

Thanks for the info.

What do you mean by ‘ appropriate academic degree lasting 3-4 years is usually required. Degrees in the fields of Computer Science, and/or engineering are suitable options.’

3-4 years of what bachelor or masters ?

Computer Science, and/or engineering : that is too generic information . Computer science itself is a part of engineering degrees . Which areas in engineering is exactly referred to ?

Also what are the recommended certificates or internships ?

Possible degree fields for a future CNC programmer are CNC machine operations, precision machining or machine technology. One well-known certificate is for example the Computer Numerical Control Certificate. I hope it helps 🙂